Tofflon Bio Division can provide the whole bio-process equipment and integrated system from media preparation, cell/microbial cultivation, harvesting, DF / UF, purification, buffer preparation, freeze & thaw systems to inactivation systems.

Case

- The microbes, insect cells, plant cells, batch / fed-batch / continuous perfusion culture of animal cells.

- Process R&D, pilot scale, commercial scale production.

- The product is applied to the macromolecular biological products such as vaccine, monoclonal antibody, insulin, genetic engineering products, recombinant protein products, etc.

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product BrochureProvide the integrated solution from membrane filtration, chromatography media screening, chromatography equipment & its process. The chromatography systems & column, UF/DF and in-line dilution systems are all involved in.

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

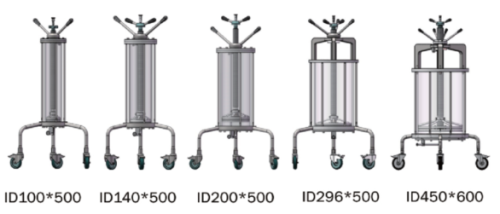

TFF is mainly applied to the concentration, separation, purification of the solutions which contain small molecule soluble and high molecular solute (such as protein, enzyme, viruses, etc.) and the manufacture of WFI. The main principle is to separate the solute under the action of the difference of static pressure.

TFF integrates the technology of several major manufacturers. In the construction of the system, the whole design and layout can be carried out according to the characteristics of different manufacturers.

Software is configured on the equipment. The user can set and automatically control the parameters such as flow rate and TMP, monitor and record all operation parameters in real-time such as volume, velocity, pressure, time, TMP, etc. which can improve the efficiency and prolong the lifetime of membrane.

TFF adopts modular design, ergonomics design, convenient operation and maintenance. Based on the highly customized ultra-filtration system, all ultrafiltration equipment can be customized according to customers’ requirement.

- All the main components are selected from well-known international manufacturers, which have superior performance and reliable quality.

- The choice of multi-flow path can provide customers for a higher automation experience.

- It will be selected for high sensitivity of on-line detector, pressure, UV, pH, conductance and other detectors.

- The software is simple and intuitive, and the interface is easy to operate.

- pH and conductivity detectors come from international brands which can realize accurate detection in the real-time by means of digital communication. The pH and conductance can be compensated for temperature as needed.

- Optimal design, no dead angle, no residue and minimum dead volume.

- Ergonomics design for simple operation and maintenance.

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product BrochureChromatography System is designed in accordance with cGMP and FDA requirements for downstream bioprocessing of biopharmaceuticals. It is fully automatic, available from pilot to industrial scale. The engineering and product quality guarantee process stability, control and reproducibility. All components from inlets to outlets in the LPLC system meet regulatory requirements which are traceable and the equipment had CIP features.

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product BrochureBio-Solution Preparation Systems provide the process auxiliary facilities for main process such as fermentation, purification, inactivation and emulsion (vaccine) process. Together with the main process equipment, a process chain is constituted, which links to the whole biopharmaceutical process.

- Media preparation and storage system

- Harvest system

- Buffer preparation and storage system

- Purification system

- CIP/SIP station

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

- Mainly used for freezing and thawing of biomacromolecules.

- Provide a repetitive, monitorable and powerful processing system.

- Suitable for R&D process, pilot test and large-scale production.

Technical Advantages

- Self-cascading cryogenic refrigeration unit for refrigeration at -75℃ or even lower. Special high-efficiency plate heat exchanger and serpentine channel circuit can not only achieve more efficient heat transfer, but also ensure more uniform temperature distribution at each point.

- Process visualization system based on Net-SCADA standard configuration software platform development, easy to maintain.

- Integrated freezing, thawing and constant temperature control.

- Electronic signature, electronic record and audit trail in compliance with USFDA 21 CFR Part 11.

- Formula management, process pre-editing to meet the pre-research needs of various products.

- Process automatically performs security monitoring and function identification.

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product BrochureSuitable for monoclonal antibodies, vaccines, insulin, protein products, blood products and biomolecules such as peptides and liposomes.

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product BrochureCOP is applied for the off-line cleaning of pharmaceutical process parts which include short pipes, hoses, fittings, clamps, gaskets and filter housing. Utilizing a recirculated design, the circulation system draws wash solutions from the tank and supplies solution back to the tank through tank jets or manifolds by the centrifugal pump.

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure

Please submit your questions to us and we will arrange service personnel to communicate with you.

Product Brochure